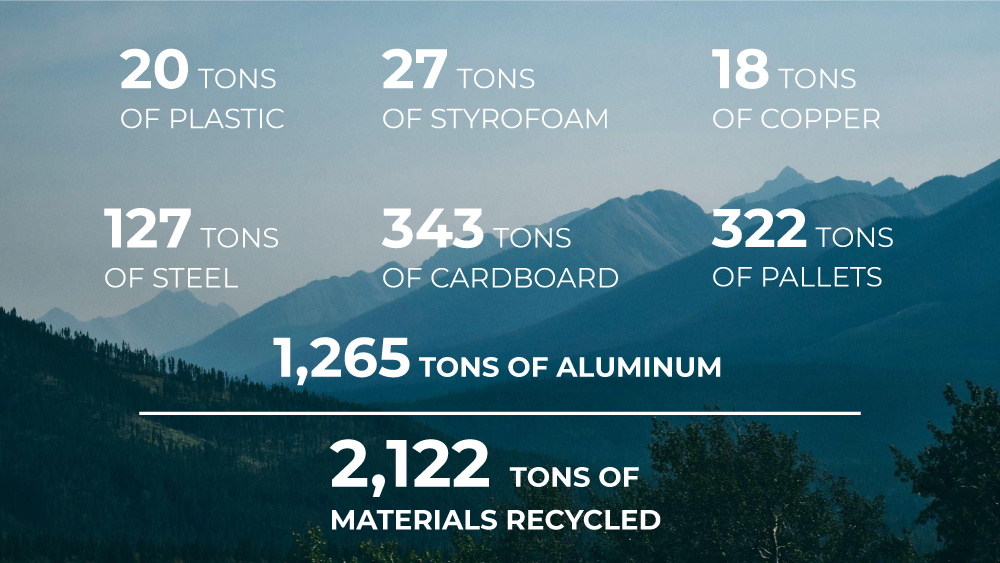

Every Airstream is manufactured with durable materials that last for generations. The vast majority of materials left over from production are recycled, and Airstream is constantly working to better understand how we can further reduce non-recyclable output during manufacturing. In addition, we’ve set our sights on a zero-waste-to-landfill goal and are continuing efforts to strengthen this already robust program that reduces waste across the business.

At the Factory

Designed for the Environment

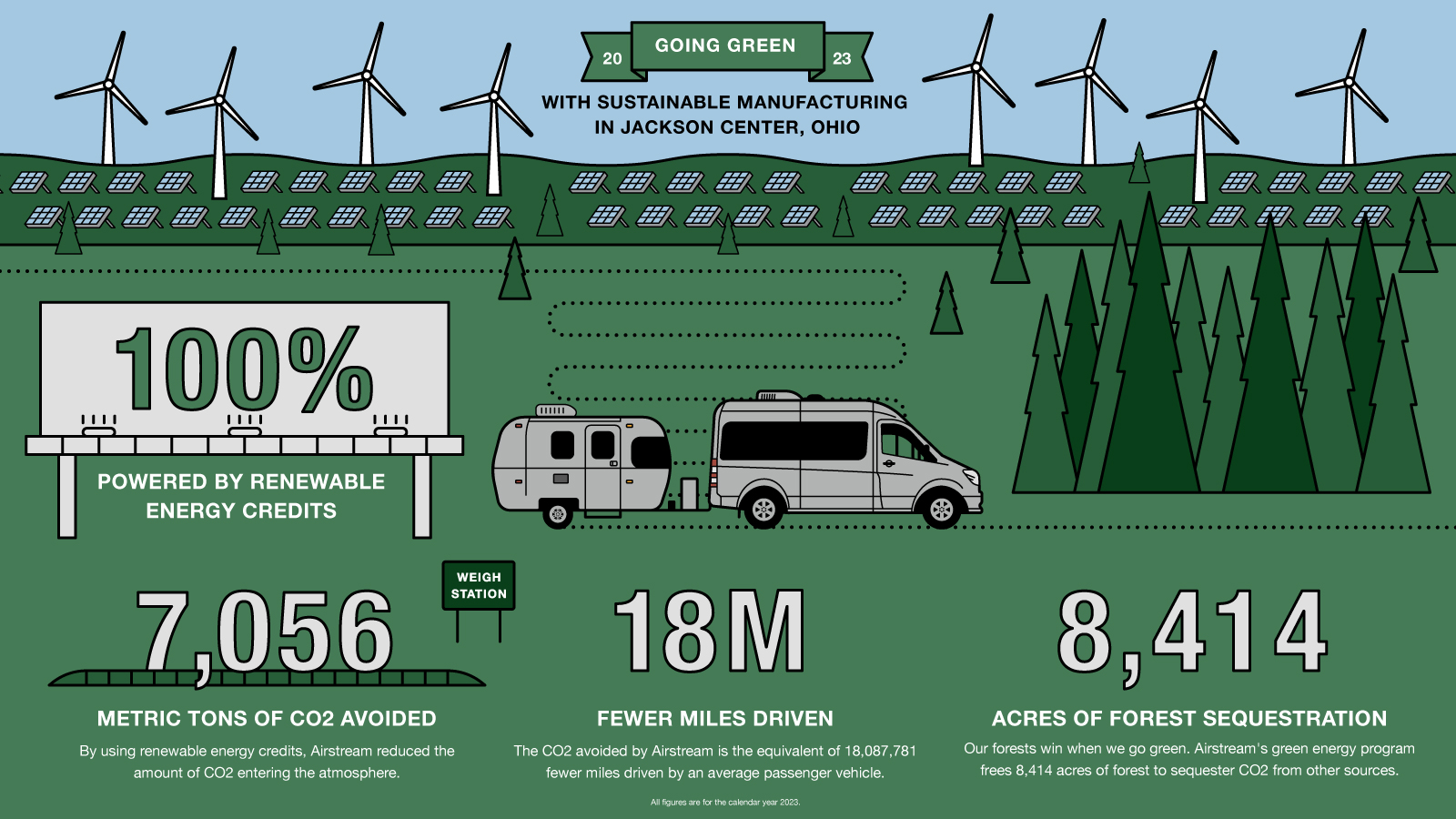

We are constantly working to further minimize the environmental impact of the Airstream manufacturing process. Airstream’s facilities in Jackson Center, Ohio, are 100%-powered by renewable energy. Through Jackson Center Municipal Power’s EcoSmart Choice program, Airstream purchases renewable energy from wind, hydroelectric, or landfill gas projects offered through American Municipal Power, Inc.

Powered by Renewable Energy

We’re choosing to be responsible stewards of the outdoors by supporting emissions-free sources of energy. In 2022, by using renewable energy, we offset 7,726 metric tons of CO2. Through renewable energy programs and ongoing initiatives to use energy-efficient lighting and machinery, we’re helping contribute to a healthier environment.

Going Further with Less

2023 Data from Internal Operations Reporting

Smart and Efficient Operations

The Airstream factory in Jackson Center is creating a smaller environmental footprint with technologies and systems that greatly increase energy efficiency and reduce waste. We have lowered our energy consumption by implementing smart technologies and equipment upgrades, including LED lighting, variable speed air compressors and highly insulated buildings.

Conversing and Recycling Water

Water used at the factory is conserved through a recycling program. In a special testing bay, each Airstream is sprayed with 10,000 gallons of water for 30 minutes while a technician monitors the inside of the vehicle for leaks. We recycle all 10,000 gallons of water used in the process through massive filters before it is reused for the next test.